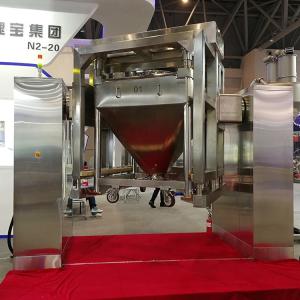

Henan Workers Machinery & Equipment Co., Ltd. (hereinafter referred

to as WKS), established for more than 10 years, is committed to the

research, manufacturing and sales of various industrial drying,

grinding, mixing, granualting and packaging machines applied in

food, pharmaceutical, nutraceutical and chemical industries, also

one of China the earliest manufacturers involved in industrial

drying equipment. WKS has a modern standard workshop, covering over

2,000 square meters; WKS more than 30 engineers from different

technical background with many years of rich research and

manufacturing experiences.

WKS mainly manufactures industrial microwave dryer, hot air

circulation dryer, multi-layer belt hot air dryer, , vibratory

fluidized bed drying equipment, spray dryer and other fruits &

vegetables and food processing machines; all of our products are

made of high quality stainless steel with mature product design and

sophisticated production technology. Therefore, the high quality

products have mush easier access to a good market reputation and

share. Our products are exported to dozens of countries such as the

United States, Canada, Britain, France, Australia, South Korea,

India, Singapore, Thailand, Malaysia, Sri Lanka, Brazil, Russia,

Uzbekistan, Romania, Croatia, Latvia, Sweden, Nigeria and South

Africa, etc.

To ensure hygiene, durability and ease of maintenance, WKS uses the

most advanced technology and materials. Whether you require a

simple conveyor or high-tech automated equipment, WKS can supply

the most suitable machine for your application. Instant supply of

in-stock spare parts ensures your machinery serviced in the

shortest time possible.

WKS believes in customer-oriented business and “quality first”

philosophy, so WKS focuses on providing customers with high quality

and technical standards products of competitive prices and warm and

thoughtful services. WKS's professional pre-sales, on-sales and

after-sales service teams will provide you with products advice,

technical details discussions, installation and commissioning,

maintenance and other services 24/7, and provide overseas technical

support and guidance if necessary.